Pasi pedingindira repasi rose rekuchengetedza simba, kuchengetedza kwezvakatipoteredza uye kushandiswa kwesimba idzva, kugadzira maindasitiri kungafamba sei kubva munzira yakasvibira yekuchengetedzwa kwezvakatipoteredza uye kuchengetedza simba?ngatitarisei mupiro welaser tekinoroji mukuchengetedza kwezvakatipoteredza uye indasitiri yegirinhi kusimudzira.

01 laser mudiwa akatendeka kuwana kabhoni peaking uye kabhoni neutralization

Laser ndeimwe yezvakagadzirwa zvikuru muzana remakore rechi20.Iine maitiro mana: kupenya kwepamusoro, kwakanaka monochromatic, kuwirirana uye kutungamira.Sezvo laser processing isiri-yekubata kugadzirisa, hapana yakananga kukanganisa pane workpiece, saka hapana mechanic deformation uye hapana ruzha rwekukanganisa;Iko hakuna "chishandiso" kupfeka uye hapana "simba rekucheka" rinoshanda pane workpiece panguva yekugadzira laser;Mukuita kwekugadziriswa kwelaser, simba remagetsi relaser beam rakakwira, kumhanya kwekugadzirisa kunokurumidza, uye iko kugadzirisa kwenzvimbo, kusina kana kushoma kukanganisa pane zvisiri laser irradiated parts.Naizvozvo, iyo inopisa yakakanganiswa nzvimbo idiki, iyo yekupisa deformation yeworkpiece idiki, uye iyo inotevera kugadzirisa ishoma.Nekuti iyo laser danda iri nyore kutungamira, kutarisa uye kuona shanduko yekutungamira, zviri nyore kwazvo kushandira pamwe neCNC system kugadzirisa yakaoma workpieces.

Naizvozvo, laser processing inzira inoshanduka uye yakareruka yekugadzirisa, ine yakanyanya kugadzirwa kunyatsoita, yakagadzikana uye yakavimbika kugadzirisa mhando, uye yakanaka yehupfumi uye yemagariro mabhenefiti.Pasina kusvibiswa kwemakemikari uye kusvibiswa kwezvakatipoteredza, ishamwari yakatendeka yekuwana kabhoni peak uye kabhoni neutralization.

02 laser kuchenesa tekinoroji yekuchenesa tekinoroji

Nekufambira mberi kwesainzi uye tekinoroji, vanhu zvishoma nezvishoma vanoongorora akasiyana matekinoroji anobatsira kuchengetedza kwezvakatipoteredza, laser yekuchenesa tekinoroji ndeimwe yacho.

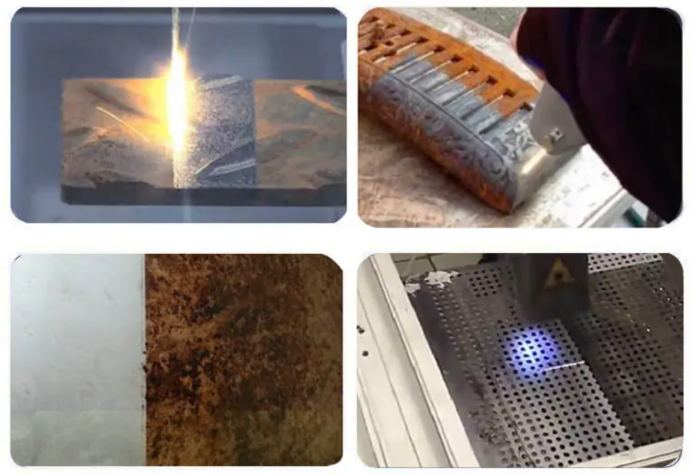

Laser yekuchenesa ndeye kushandisa yakakwira-simba laser beam kuti iwirirane nezvinhu zvinobviswa pamusoro peiyo workpiece, kuitira kuti zvakabatanidzwa zvinogona kubuda kana kupepeta ipapo ipapo kuti uwane chinangwa chekuchenesa workpiece.Iyi tekinoroji yekugadzira haidi akasiyana makemikari ekuchenesa maajenti, uye yakasvibira uye isina kusvibiswa-isina.Inoshandiswa zvakanyanya mukubvisa pendi yependi uye depainting, tsvina yemafuta epamusoro, kuchenesa tsvina, kupeta kwepamusoro uye kubviswa kwependi, welding pamusoro / kupfapfaidza pamusoro pekutangira, guruva uye zvakanamirwa kubviswa pamatombo, kuchenesa rabha mold, nezvimwe.

Nzira dzechinyakare dzekuchenesa, dzinosanganisira kuchenesa michina, kuchenesa makemikari uye kuchenesa kwe ultrasonic, inoburitsa zvinosvibisa kune akasiyana madhigirii.Pasi pezvinodiwa zvekuchengetedzwa kwezvakatipoteredza uye nepamusoro-soro, kushandiswa kwavo kune zvishoma.Iyo laser yekuchenesa maitiro haiburitse chero zvinhu zvinokuvadza, izvo zvinogona kunzi zvakatipoteredza zvine hushamwari kuchenesa.

Kuenzaniswa nemaitiro echinyakare ekuchenesa, laser yekuchenesa i "girinhi" yekuchenesa nzira, ine mabhenefiti asingaenzaniswi: haidi kushandisa chero makemikari ejenti uye yekuchenesa mvura, uye tsvina mushure mekuchenesa iine hupfu hwakasimba, ine vhoriyamu diki, nyore. kuchengetedza, adsorption uye kupora, hapana photochemical reaction, hapana ruzha uye kusvibiswa kwezvakatipoteredza.Panguva imwecheteyo, zviri nyore kuona kudzora otomatiki uye kuchenesa kure kure pasina kukuvadza hutano hwevashandisi.

03 kuchengetedzwa kwezvakatipoteredza mupiro we "fiber laser tekinoroji"

Seimwe yeanonyanya kuvimbisa matekinoroji muzana ramakore rechi21, tekinoroji yelaser iri kuitawo basa rakakosha mukuchenesa nharaunda yatinogara.Kubuda uye kushandiswa kwelaser kunonzi kusvetuka kwechitatu kwezvishandiso zvevanhu.Kuti isangane nezvinodiwa zveshanduko uye kusimudzira indasitiri yekugadzira, laser tekinoroji ichatungamira iyo indasitiri yekugadzira kusimudzira munzira yekushanda kwakanyanya, kuchengetedza simba, kuchengetedza kwezvakatipoteredza uye hungwaru.

Iyo electro-optical shanduko yekugona kwefiber laser yakakwirira.Kuenzaniswa nemamwe ma lasers, iyo electro-optical conversion rate yefiber laser i30%, iyo YAG solid-state laser inongova 3%, uye iyo CO2 laser i10%;Iyo yepakati yepakati mune yechinyakare laser inofanira kutonhodzwa nemvura.Fiber laser inoshandisa faibha sekuwana svikiro uye ine yakakura pamusoro penzvimbo / vhoriyamu reshiyo, inoita kuti ive yakanaka kwazvo kupisa kupisa kuita.Panguva imwecheteyo, iyo yakavharwa yese fiber chimiro inovimbisa kugadzikana kweiyo laser cavity.Nekuda kweaya akasarudzika maitiro efiber lasers, izvo zvinotonhora zvinodiwa zvefiber lasers zvakaderedzwa zvakanyanya.Yakaderera simba faibha lasers inongoda kushandisa kutonhora kwemhepo, kutsiva kutonhora kwemvura zvinodiwa zvechinyakare lasers, kuitira kuchengetedza magetsi nemvura uye kuita mipiro mukuchengetedza simba uye kuderedza kubuda.

04 laser inobatanidza kuchengetedza kwesimba, kuchengetedza kwezvakatipoteredza, kuderedza emission uye yakaderera kabhoni

Mumakore achangopfuura, senzira yepamusoro yekugadzirisa, laser processing zvishoma nezvishoma yakatsiva akawanda echinyakare nzira dzekugadzirisa.Muminda yekumaka, welding, kucheka, kuchenesa, kuvhara uye kuwedzera kugadzira, laser processing yakaratidza zvishoma nezvishoma zvakanakira zvisingaenzaniswi.

Semuyenzaniso, nekuvandudzwa kwenguva, akasiyana siyana laser ekuchenesa matekinoroji ayo anobatsira kudzivirira kwezvakatipoteredza anobuda sezvinodiwa nenguva;Semuenzaniso, lidar inogona kunyatsoongorora nzvimbo yenzvimbo, nzvimbo yekusvibiswa uye kuitika kwehuwandu hwezvinyorwa zvinosvibisa, kufungidzira pamusoro pezvinhu zvinosvibisa uye zvinokonzera kusvibiswa, uye kunyatsovandudza kushanda kwekugadzirisa kusvibiswa kwemhepo;Laser kuchenesa nepamusoro kunyatsoshanda uye yakaderera mutengo pane zvechinyakare nzira;Kune mwenje welaser unopenya kupfuura marambi eLED, madiki muhukuru, akawanda-anochengetedza simba, kureba mukurebesa kureba uye mamwe ekuchengetedza simba;Iyo imwe nzira ye electroplating tekinoroji yave kubvumirana muindasitiri.Iyo laser cladding tekinoroji inozivikanwa nemusika mutengo wayo wakaderera, zero kusvibiswa, hupenyu hwakareba uye yakaderera mashandisiro emagetsi tekinoroji yakaderera-kabhoni ine simba rekuchengetedza, kuchengetedza kwezvakatipoteredza uye kuderedza emission.

Kuziva kabhoni peaking uye kabhoni neutralization chinhu chinodikanwa chekusimudzira kusimudzira kwemhando yepamusoro.Tinofanira kunyatsoinzwisisa uye nekuisimudzira tisingazununguki.Kuti izvi zviitike, isu tinofanirwa kutevedzera nzira yemhando yepamusoro yekusimudzira kwezvakatipoteredza, zvakasvibira uye zvakaderera-kabhoni, kutora nguva yakakosha uye nguva yehwindo ye "14th chirongwa chemakore mashanu" kuti tisvike panhongonya yekabhoni, takashinga kutakura zvematongerwo enyika. mutoro wekuchengetedza kwezvakatipoteredza, tora danho uye uite zvipo zvakanaka kukurumidza kuvakwa kweGreater China yakanaka ine denga rebhuruu, nyika yakanaka uye mvura yakanaka.

Nguva yekutumira: Aug-25-2022