Laser pamusoro pekurapa tekinoroji inoshandisa yakakwira simba density laser danda kupisa iyo yepasi pasi nenzira isiri-yekubata, uye inoziva kugadziridzwa kwayo kwepamusoro kuburikidza nekutonhorera kutonhora kwechinhu chacho pachayo.Izvo zvinobatsira kuvandudza michina uye yemuviri zvimiro zvepasi pezvinhu, pamwe nekupfeka kuramba, corrosion resistance uye kuneta kuramba kwezvikamu.Mumakore achangopfuura, laser pamusoro pekurapa tekinoroji senge laser kuchenesa, laser quenching, laser alloying, laser shock kusimbisa uye laser annealing, pamwe nelaser cladding, laser 3D kudhinda, laser electroplating uye humwe hunyanzvi hwekugadzira laser hwakaunza tarisiro yakakura yekushandisa. .

1. Laser kuchenesa

Laser kuchenesa inokurumidza kuvandudza tekinoroji yekuchenesa pamusoro, inoshandisa yakakwirira-simba pulse laser beam kuvhenekesa pamusoro peiyo workpiece, kuitira kuti tsvina, zvimedu kana kupfekwa pamusoro zvinogona kubuda kana kuwedzera ipapo, nekudaro kuwana maitiro ekuchenesa. nokucheneswa.Laser yekuchenesa inonyanya kukamurwa kuita ngura kubvisa, kubviswa kwemafuta, kubviswa kwependi, kubvisa kupfekedza uye mamwe maitiro;Inonyanya kushandiswa kucheneswa kwesimbi, kuchenesa zvisaririra zvetsika, kuchenesa zvivakwa, etc. Kubva pamabasa ayo akazara, akarurama uye anochinjika kugadzirisa, kushanda kwakanyanya uye kuchengetedza simba, girinhi kuchengetedzwa kwezvakatipoteredza, hapana kukuvadza kune substrate, njere, yakanaka yekuchenesa mhando, kuchengeteka, kushandiswa kwakakura uye humwe hunhu uye zvakanakira, zvave kuwedzera mukurumbira munzvimbo dzakasiyana dzeindasitiri.

Kuenzaniswa nenzira dzechinyakare dzekuchenesa dzakadai semechani friction yekuchenesa, makemikari corrosion kuchenesa, mvura yakasimba yakasimba simba kuchenesa, yakakwira-frequency ultrasonic kuchenesa, laser kuchenesa kune zvakanakira zviri pachena.

2. Laser quenching

Laser quenching anoshandisa yakakwirira-simba Laser sezvo kupisa sosi kuita simbi pamusoro kupisa uye kutonhora nokukurumidza.Iyo yekudzima nzira inopedzwa pakarepo kuti uwane kuomarara kwakanyanya uye Ultra-yakanaka martensite chimiro, kuvandudza kuomarara uye kupfeka kuramba kwesimbi, uye kuumba compressive kushushikana pamusoro pepamusoro kuvandudza kuneta kuramba.Mabhenefiti epakati peiyi maitiro anosanganisira diki kupisa kwakakanganisika nzvimbo, diki deformation, yakakwira degree re otomatiki, kuchinjika kwakanaka kwekusarudza kudzima, kuoma kwakanyanya kwezviyo zvakanatswa, uye nehungwaru kuchengetedza kwezvakatipoteredza.Semuyenzaniso, Laser nzvimbo inogona kugadziriswa kudzima chero hupamhi nzvimbo;Kechipiri, iyo laser musoro uye iyo yakawanda axis robhoti yekubatanidza inogona kudzima nzvimbo yakatarwa yezvikamu zvakaoma.Kune mumwe muenzaniso, laser quenching inopisa zvakanyanya uye nekukurumidza, uye kudzima kushushikana uye deformation idiki.Iyo deformation ye workpiece isati yasvika uye mushure mekudzima laser inogona kunge isina kufuratirwa, saka inonyanya kukodzera kurapwa kwepamusoro kwezvikamu zvine zvinodiwa zvakanyanya.

Parizvino, laser quenching yakashandiswa zvakabudirira pakusimbaradza kwepamusoro kwezvikamu zviri munjodzi muindasitiri yemotokari, indasitiri ye mold, maturusi emidziyo uye indasitiri yemuchina, kunyanya mukuvandudza hupenyu hwebasa rezvikamu zviri munjodzi senge magiya, shaft nzvimbo, madhairekitori, shaya uye. molds.Maitiro ekudzima laser ndeaya anotevera:

(1) Laser quenching inokurumidza kudziyisa uye kuzvifadza kutonhora maitiro, izvo zvisingade kuchengetedza kupisa kwechoto uye kudzima kunotonhorera.Iyo inosvibisa-isina, yakasvibira uye yakasvibira-inoshamwaridzika kupisa kupisa maitiro, uye inogona kuita nyore yunifomu kudzimisa pamusoro pezviumbwa zvakakura;

(2) Sezvo iyo laser yekudziya yekumhanyisa ichimhanya, iyo inopisa yakakanganiswa nzvimbo idiki, uye pamusoro pekutarisa kupisa kudzima, kureva, pakarepo kupisa kwenzvimbo kudzima, deformation yeyakarapwa kufa idiki kwazvo;

(3) Nekuda kwediki divergence angle yelaser beam, ine yakanaka yakanangana, uye inokwanisa kunyatso kudzima mold pamusoro kuburikidza nemwenje dhizaini system;

(4) Iyo yakaomeswa kudzika kwelaser surface quenching kazhinji 0.3-1.5 mm.

3. Laser annealing

Laser annealing inzira yekupisa kupisa iyo inoshandisa laser kupisa iyo yezvinhu, kufumura zvinhu kune tembiricha yakanyanya kwenguva yakareba, uye wozoitonhodza zvishoma nezvishoma.Chinangwa chikuru cheichi chiitiko ndechekusunungura kushushikana, kuwedzera zvinhu ductility uye kuoma, uye kugadzira yakakosha microstructure.Iyo inoratidzirwa nekukwanisa kugadzirisa matrix chimiro, kuderedza kuoma, kunatsa zviyo uye kubvisa kushushikana kwemukati.Mumakore achangopfuura, laser annealing tekinoroji yavewo nzira nyowani muindasitiri yekugadzira semiconductor, iyo inogona kuvandudza zvakanyanya kubatanidzwa kwemaseketi akabatanidzwa.

4. Laser kuvhunduka kusimbisa

Laser shock inosimbisa tekinoroji inyowani uye yakakwira tekinoroji inoshandisa iyo plasma yekuvhundutsa wave inogadzirwa neakasimba laser beam kuvandudza anti kuneta, kupfeka kuramba uye kusakara kwesimbi zvinhu.Iyo ine zvakawanda zvakatanhamara zvakanakira, senge isina kupisa kwakakanganisika nzvimbo, yakakwirira simba rekushandisa, Ultra-yakakwira strain rate, yakasimba controllability uye zvinoshamisa kusimbisa maitiro.Panguva imwecheteyo, laser shock inosimbisa ine hunhu hwekudzika kwakasara compressive kusagadzikana, nani microstructure uye kutendeseka kwepamusoro, zvirinani kugadzikana kwemafuta uye hupenyu hurefu.Mumakore achangopfuura, tekinoroji iyi yakawana kukurumidza kusimudzira, uye ine basa rakakura mune zvemuchadenga, kudzivirira kwenyika uye indasitiri yemauto nemamwe minda.Mukuwedzera, iyo yekuputira inonyanya kushandiswa kuchengetedza workpiece kubva pakupisa laser uye kuwedzera kunyura kwelaser simba.Parizvino, izvo zvinowanzoshandiswa zvekupfekedza zvinhu ndeyependi yakasviba uye aluminium foil.

Laser peening (LP), inozivikanwawo selaser shock peening (LSP), inzira inoshandiswa mumunda weinjiniya yepasi, ndiko kuti, kushandiswa kweiyo pulsed yakakwirira-simba laser matanda kuburitsa kusara kushushikana mumidziyo yekuvandudza kusapfeka. (sekupfeka kuramba uye kuramba kuneta) kwenzvimbo dzezvinhu, kana kuvandudza kusimba kwezvikamu zvitete zvezvinhu kuwedzera kuoma kwepasi kwezvinhu.

Kusiyana nezvakawanda zvekugadzirisa zvikumbiro, LSP haishandise laser simba rekurapa kupisa kuti iwane mhedzisiro yaunoda, asi inoshandisa danda kukanganisa kwemuchina kugadzirisa.Yakakwira simba laser beam inoshandiswa kubata pamusoro peiyo inotarirwa workpiece ine yakakwira simba pfupi pulse.

Iyo mwenje wemwenje inobata simbi yekushanda, inoputira iyo workpiece kuita yakatetepa plasma mamiriro nekukasira, uye inoshandisa shock wave pressure kune workpiece.Dzimwe nguva mutete wakatsetseka we opaque cladding zvinhu unowedzerwa kune workpiece kutsiva simbi evaporation.Kudzvanyirira, zvimwe zvinhu zvakajeka zvekupfeka kana inertial interference layers zvinoshandiswa kutora plasma (kazhinji mvura).

Plasma inogadzira shock wave effect, inogadziridza iyo yepamusoro microstructure yeworkpiece panzvimbo yekubata, uye yobva yagadzira ketani yekuwedzera kwesimbi nekutsikirira.Iyo yakadzika yekumanikidza kushushikana inogadzirwa nekuita uku inogona kuwedzera hupenyu hwechikamu.

5. Laser alloying

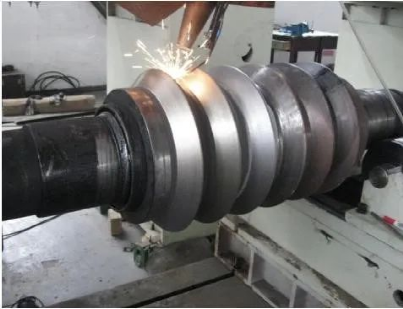

Laser alloying inyowani yekugadziridza tekinoroji tekinoroji, inogona kushandiswa kugadzirira amorphous nanocrystalline yakasimbiswa cermet composite coatings pamusoro pezvikamu zvezvimiro zvinoenderana neakasiyana sevhisi mamiriro ezvishandiso zvendege uye hunhu hwepamusoro simba density laser beam kupisa uye condensation rate, saka. sekuzadzisa chinangwa chekugadziriswa kwepasi kwezvinhu zvekubhururuka.Kuenzaniswa nelaser alloying tekinoroji, laser cladding tekinoroji ine hunhu hwediki dilution reshiyo ye substrate kune yakanyungudutswa dziva, diki kupisa kwakakanganisika nzvimbo, diki yekupisa deformation yeworkpiece uye diki chirahwe mwero weworkpiece mushure melaser cladding kurapwa.Laser cladding inogona kuvandudza zvakanyanya pamusoro pezvinhu zvezvinhu, uye kugadzirisa zvakasakara zvinhu.Iyo ine hunhu hwepamusoro-soro, kukurumidza kukurumidza, girini kuchengetedza kwezvakatipoteredza uye kusvibiswa-isina, uye kuita kwakanaka kweiyo workpiece mushure mekurapwa.

Laser cladding tekinoroji zvakare imwe yeayo matsva ekugadzirisa tekinoroji inomiririra danho rekusimudzira uye nhanho yeinjiniya yepasi.Laser cladding tekinoroji yave hotspot yekutsvagisa mukugadziriswa kwepamusoro kwetitanium alloys nekuda kwemabhenefiti ayo ekusvibisa-isina uye simbi musanganiswa pakati pejasi uye substrate.Laser cladding ceramic coating kana ceramic particle yakasimbiswa composite coating inzira inoshanda yekuvandudza pamusoro kupfeka kuramba kwetitanium alloy.Zvinoenderana nemamiriro chaiwo ekushanda, sarudza iyo yakakodzera zvinhu sisitimu, uye iyo laser cladding tekinoroji inogona kuwana zvakanakisa maitiro zvinodiwa.Laser cladding tekinoroji inogona kugadzirisa akasiyana akakundikana zvikamu, senge aeroengine blades.

Musiyano uripo pakati pelaser surface alloying nelaser surface cladding ndewekuti laser surface alloying ndeyekusanganisa zvizere iyo yakawedzera alloy element uye iyo yepamusoro layer ye substrate mune yemvura mamiriro kuti iite alloying layer;Laser surface cladding ndeyekunyungudutsa ese precoating uye micro inonyungudutsa substrate pamusoro, kuitira kuti cladding layer uye substrate zvinhu zvinogadzira metallurgical musanganiswa uye kuchengetedza kuumbwa kweiyo cladding layer isingachinjike.Laser alloying uye laser cladding tekinoroji inonyanya kushandiswa kuvandudza pamusoro kupfeka kuramba, corrosion kuramba uye grading kuramba kwetitanium alloys.

Parizvino, laser cladding tekinoroji yakashandiswa zvakanyanya mukugadzirisa uye kuchinjisa nzvimbo dzesimbi.Nekudaro, kunyangwe yechinyakare laser cladding ine mabhenefiti uye hunhu hwekuchinjika kugadzirisa, yakasarudzika-yakaita gadziriso, mushandisi-inotsanangurwa yekuwedzera, nezvimwewo, kushanda kwayo kwakanaka kwakadzikira, uye haisati yakwanisa kuzadzisa zvinodiwa zvehukuru-hukuru kukurumidza kugadzirwa uye kugadzirisa mukati. dzimwe minda yekugadzira.Kuti isangane nezvinodiwa zvekugadzirwa kwakawanda uye kuvandudza kugona kwekupfekedza, yakakwira-kumhanya laser cladding tekinoroji yakatanga.

High speed laser cladding tekinoroji inogona kuona compact uye kuremara yemahara cladding layer.Hunhu hwepamusoro hweiyo cladding layer ndeye compact, metallurgical bonding ne substrate, hapana chakavhurika chakaremara, uye pamusoro pacho pakatsetseka.Haikwanise kugadziriswa chete pamutumbi unotenderera, asiwo pane ndege uye yakaoma pamusoro.Kuburikidza nekuenderera mberi kwehunyanzvi hwekugadzirisa, tekinoroji iyi inogona kushandiswa zvakanyanya mumarasha, simbi, mapuratifomu ekumahombekombe, kugadzira mapepa, midziyo yevagari, mota, ngarava, peturu, maindasitiri emuchadenga, uye kuita girinhi remanufacturing process inogona kutsiva yechinyakare electroplating tekinoroji.

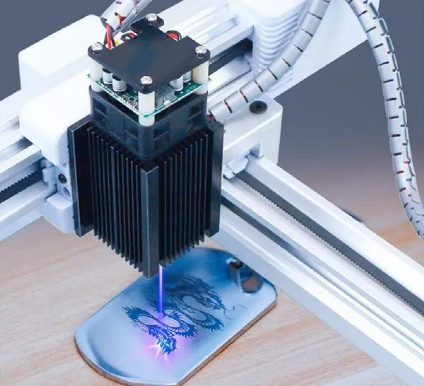

7. Laser engraving

Laser engraving ndeye laser process process inoshandisa CNC tekinoroji purojekiti yakakwira-simba laser beam pane chinhu chepamusoro, uye inoshandisa iyo inopisa mhedzisiro inogadzirwa nelaser kugadzira mapatani akajeka pamusoro pezvinhu.Iyo yemuviri denaturation yekunyunguduka uye gasification yekugadzira zvinhu pasi pekuvhenekesa kwelaser engraving inogona kugonesa laser engraving kuzadzisa zvinangwa zvekugadzirisa.Laser engraving ndeye kushandisa laser kunyora mazwi pachinhu.Mazwi akavezwa neiyi tekinoroji haana nicks, pamusoro pechinhu chakatsetseka uye chakapfava, uye runyoro harupfekwe.Zvimiro zvayo uye zvakanakira zvinosanganisira: yakachengeteka uye yakavimbika;Yakarurama uye inongwarira, iyo chaiyo inogona kusvika 0.02mm;Chengetedza kuchengetedza kwezvakatipoteredza uye zvinhu panguva yekugadzirisa;High speed, high speed engraving maererano nezvakabuda mifananidzo;Mutengo wakaderera, usina kuganhurirwa nehuwandu hwekugadzirisa, nezvimwe.

8. Laser 3D kudhinda

Maitiro acho anotora tekinoroji yelaser cladding, iyo inoshandisa laser kunyungudutsa poda inoyerera inotakurwa nemuromo kunyungudutsa zvakananga chinhu chiri nyore kana alloy poda.Mushure mekunge danda relaser rasiya, iyo alloy fluid inosimba nekukurumidza kuti ione nekukurumidza prototyping yealloy.Parizvino, yakashandiswa zvakanyanya muindasitiri yekuenzanisira, kugadzira michina, aerospace, mauto, zvivakwa, firimu uye terevhizheni, midziyo yemumba, indasitiri yemwenje, mushonga, matongo, tsika uye hunyanzvi, zvivezwa, zvishongo nemimwe minda.

9. Yakajairika maindasitiri ekushandisa kwelaser pamusoro kurapwa uye remanufacturing

Parizvino, laser pamusoro pekurapa uye yekuwedzera yekugadzira matekinoroji, maitiro uye michina inoshandiswa zvakanyanya musimbi, migodhi muchina, molds, peturu simba, hardware maturusi, njanji yekufambisa, aerospace, michina uye mamwe maindasitiri.

10. Kushandiswa kwelaser electroplating teknolojia

Laser electroplating inyowani yakakwira-energy danda electroplating tekinoroji, iyo yakakosha zvikuru pakugadzira nekugadzirisa mamicroelectronic madivayiri uye makuru-akabatanidzwa maseketi.Parizvino, kunyangwe musimboti welaser electroplating, laser ablation, plasma laser deposition uye laser jet vachiri pasi pekutsvagirwa, matekinoroji avo akashandiswa.Kana iyo inoenderera mberi laser kana pulse laser inovhenekera iyo cathode pamusoro muye electroplating yekugezera, kwete chete iyo deposition rate yesimbi inogona kuvandudzwa zvakanyanya, asiwo komputa inogona kushandiswa kudzora trajectory yelaser beam kuti iwane iyo isina kuvharidzirwa coating ye. inotarisirwa yakaoma geometry.

Iko kushandiswa kwelaser electroplating mukuita kunonyanya kuenderana neaya anotevera maitiro:

(1) Kumhanya munzvimbo yelaser irradiation yakakura kupfuura kumhanya kwe electroplating mumuviri (kanenge ka103);

(2) Kugona kutonga kwelaser kwakasimba, izvo zvinogona kuita kuti chikamu chinodiwa chechinhu chiwedzere huwandu hunodiwa hwesimbi.Ordinary electroplating inoitika pane yose electrode substrate, uye electroplating speed inononoka, saka zvakaoma kuumba maitiro akaoma uye akanaka.Laser electroplating inogona kugadzirisa iyo laser danda kune micrometer saizi, uye kuitisa isina kuvharwa yekutevera pane micrometer saizi.Kune dhizaini yedunhu, kugadzirisa dunhu uye dhizaini yemunharaunda pane microelectronic connector components, iyi mhando yehigh-speed mepu iri kuramba ichiwedzera kushanda.

Kuenzaniswa neyakajairwa electroplating, mabhenefiti ayo ndeaya:

(1) Inokurumidza kuisa kukurumidza, senge laser goridhe plating inosvika 1 μ M/s, laser mhangura inonamatira inosvika 10 μ M/s, laser jet goridhe plating inosvika 12 μ M/s, laser jet copper plating inosvika makumi mashanu. μ m/s;

(2) Metal deposition inongoitika munzvimbo yelaser irradiation, uye yemuno deposition coating inogona kuwanikwa pasina ekudzivirira matanho, nekudaro kurerutsa maitiro ekugadzira;

(3) Iyo yekunamatira yekunamatira inovandudzwa zvakanyanya;

(4) Zviri nyore kuona otomatiki kudzora;

(5) Chengetedza simbi dzinokosha;

(6) Chengetedza mari yekushandisa uye nguva yekugadzirisa.

Kana iyo inoenderera mberi laser kana impulse laser inovhenekera iyo cathode pamusoro muye electroplating bath, kwete chete iyo deposition rate yesimbi inogona kuvandudzwa zvakanyanya, asiwo komputa inokwanisa kudzora track yekufamba kwelaser beam kuti iwane iyo isina kuvharidzirwa coating neinotarisirwa yakaoma. geometry.Irizvino tekinoroji nyowani yelaser jet yakakwidziridzwa electroplating inosanganisa iyo laser yakawedzera electroplating tekinoroji neiyo electroplating mhinduro yekupfapfaidza, kuitira kuti laser uye plating mhinduro inogona panguva imwe chete kupfura kune cathode pamusoro, uye misa yekufambisa inokurumidza kupfuura iyo misa yekumhanyisa kumhanya. yeiyo micro inobvongodza inokonzerwa nelaser irradiation, nekudaro kuwana yakakwira deposition kumhanya.

Kubudirira kweramangwana uye hutsva

Mune ramangwana, iyo nzira yekusimudzira yelaser yepamusoro kurapwa uye yekuwedzera yekugadzira michina inogona kupfupikiswa sezvinotevera:

·Kushanda kwepamusoro - kushanda kwepamusoro-soro, kusangana nekukasira kwekugadzira rhythm yeindasitiri yemazuva ano;

·Kushanda kwepamusoro - midziyo ine mabasa akasiyana-siyana, kushanda kwakadzikama uye inokodzera mamiriro ekushanda akasiyana;

·Ungwaru hwepamusoro - chiyero chenjere chiri kuramba chichivandudzwa, pasina kupindira kwemaoko;

·Mutengo wakaderera - mutengo wemidziyo unodzoreka, uye mutengo wezvekushandisa unodzikiswa;

·Kugadziridza - yakasarudzika yakasarudzika yemidziyo, chaiyo mushure mekutengesa sevhisi,

·Uye kusanganisa - kusanganisa tekinoroji yelaser neyechinyakare yekugadzirisa tekinoroji.

Nguva yekutumira: Sep-17-2022