Mumakore achangopfuura, inotungamirwa nemagetsi tekinoroji uye 5G tekinoroji, maitiro ezvigadzirwa zvemagetsi zvepasi rose zvichive zvitete uye kunyatsojeka zvave pachena.Pasi pekuda kwemutengi kutsungirira kwakanyanya, kuchengetedzeka kwepamusoro uye kusarudzika kwezvigadzirwa zvemagetsi, vagadziri vakuru vemabhatiri vari kukwikwidzawo zvishoma nezvishoma kugadzira mabhatiri matsva anochajiswa ane simba repamusoro uye zvirevo zvakasiyana uye zvinhu.Nekuomerwa kuri kuwedzera mukugadzirisa mabhatiri matsva, tekinoroji yekugadzirisa tekinoroji yakaoma kugadzirisa marwadzo ebhatani idzva rekugadzirisa bhatiri tekinoroji.Kuenzaniswa neyechinyakare yekugadzira tekinoroji, iyo laser welding tekinoroji, nekuda kwekuwanda kwayo kwakanakira, inokwanisa kusangana nekusiyana kwebhatani rekugadzirisa bhatiri tekinoroji, kuderedza kukuvadzwa kwebhatiri uye kudzivirira kutambisa zvinhu.Inotevera inotsanangura mashandisirwo elaser welding tekinoroji mumabhatiri ekuwelda mabhatani.

Bhatani bhatiri welding pini yakaoma.Kana kushanda kusina kunaka, bhatiri rinokuvadzwa nyore nyore nekuputika (pfupi pfupi inokonzerwa nemukati diaphragm welding) kana solder pad iri nyore kudonha.Nekuti bhatani bhatiri idiki uye rakatetepa, unprofessional spot welding ichaita kukuvadza kukuru kune bhatani bhatiri, kunyanya kune yakaipa danda rebhatani bhatiri.Iyo yakaipa pole shell yakafukidzwa ne lithium simbi, iyo ine yakanaka kwazvo conductivity uye yekupisa conductivity.Iyo lithium simbi inosangana zvakananga nemukati diaphragm (kuparadzanisa zvinhu zvakanaka uye zvisina kunaka) yebhatiri, saka nzira isina kufanira yenzvimbo yewelding inogona kukonzera kukuvadzwa kwebhatiri diaphragm, izvo zvinokonzeresa kupfupika kwemukati kwebhatani bhatiri.

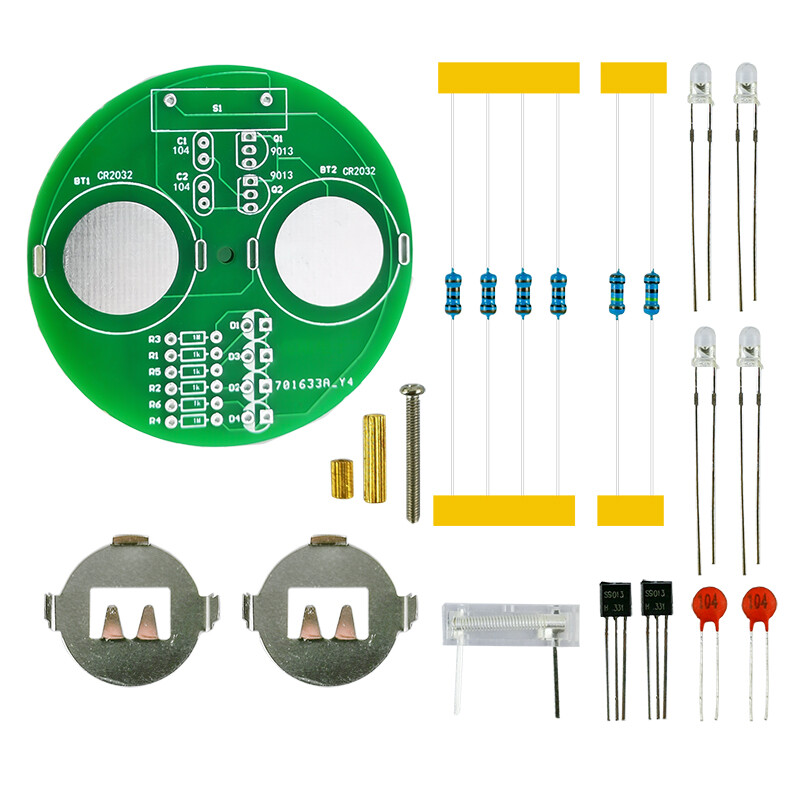

Laser application process yebhatani bhatiri:

Laser application process yebhatani bhatiri:

1.Shell uye ndiro yekuvhara: laser etching yebhatani simbi shell;

2.Magetsi musimboti chikamu: kubatanidza matanda akanaka uye asina kunaka eiyo inomonereka musimboti ane chivharo cheganda, laser welding chivharo chegoko negoko, uye kubatanidza zvipikiri zvekuisa chisimbiso;

3.PACK chikamu chemodule: electric core screening, side pasting, positive uye negative electrode welding, post welding inspection, saizi yekuongorora, epamusoro neakadzika adhesive tepi, air tightness inspection, blanking sorting, etc.

Paunenge uchishandisa bhatani bhatiri, zvinodikanwa kuti weld lug terminal pabhatiri.Iyo yakajairika welding nzira ndeye chaiyo laser nzvimbo welding.Kugamuchirwa kwechaiyo laser spot welding kunogona kunyatso kudzivirira uye kugadzirisa matambudziko aripo mune akajairwa-akawanda-frequency nzvimbo welding, kuitira kuti maseru kuti aonekwe akaiswa welds ane mashoma enhema welds, akasimba welding makwapa, kuenderana kwakanaka, uye dzakanaka uye dzakatsvinda nzvimbo dzewelding.Kunyanya, iyo yemuno welding pakati pesero inotarisana nelaser spot welding ipfupi, saka hapana chinoputsika chiitiko.

Izvo zviri pamusoro ndiyo mashandisirwo ekushandiswa kwelaser welding tekinoroji mumabhatiri ekuwelda mabhatani.Kunyangwe laser welding tekinoroji yakashandiswa zvakanyanya mukugadzira bhatani remhando bhatiri, ichiri kufanira kutarisisa tekinoroji yekugadzira kuti uwane yakanaka welding mhedzisiro!

Nguva yekutumira: Zvita-08-2022