Fixture System yeLaser Brazing

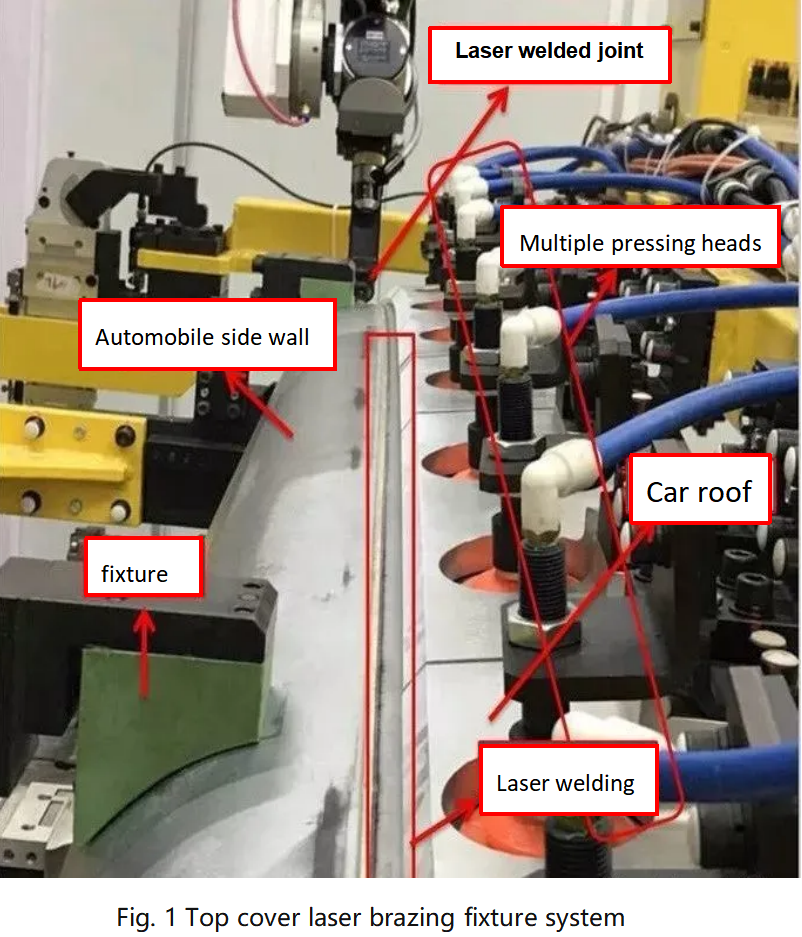

Munguva yekushivirira kwelaser, zvinodikanwa kusungirira simbi yakashongedzwa zvakasimba zvakakwana, saka machira akakosha anozogadzirwa.Iyo laser welding fixture ine yakakura vhoriyamu uye yakaoma chimiro.Icho chimiro chefuremu yose.Mativi ekuruboshwe nekurudyi emuviri wemotokari anotsigirwa nemabhuraki ekugadzirisa uye anosungirirwa nemasilinda mushure mekugadzwa uye kutsigirwa.Chikamu chepamusoro chakagadzirwa nechakasarudzika chinzvimbo uye kudzvanya gripper yelaser brazing yedenga remotokari, iyo inodzvanywa nemisoro yakawanda yekutsikirira.Robhoti rinobata denga, roriisa pamuviri, uye rinosungirira necylinder, kuitira kuti micheto yemuviri simbi ndiro kuti isungirwe kukwana zvakakwana.Sezvakaratidzwa mumufananidzo 1.

Process factor

• · Tembiricha

• · Angle yechiitiko che laser beam

• · Aggregation uye defocus

• · Kupinza kudzika kwewelding

• · Mhedzisiro yekumhanyisa kumhanya pane laser welding simba

Test

• 、Kuongorora kwekuona

• · Maererano neGermany standard PV 6917 (inogona kuwanikwa nekubata munyori);

• Ongororo yezviono ichaitwa pagungano rega rega rega pasina tambo;

• Kutarisa pakuona kupinza kwe weld (sekupinda kusina kukwana, pamusoro pekupinda uye kupisa mukati), uye funga nezvemamiriro epamusoro e weld (zvakadai se spatter uye porosity);

Iyo nzira yekuongorora yelaser brazing yekutarisa yekuona inoratidzwa muTafura 1.

| Tafura 1 Kuonekwa Kwemhando Yekuongororwa kweLaser Brazing | ||

| Seri Nha | Defect tsananguro | Kukanganisa kuongorora |

| 1 | Exposed pores | Kana mamiriro ezvinhu achibvumira, nzvimbo yacho inogona kugadziriswa chero bedzi isingakanganisi basa;Makomba emhepo ane dhayamita anopfuura 0.2mm anofanira kugadziriswa |

| 2 | Solder mafashama (yakawanda) | Kana mamiriro ezvinhu achibvumira, nzvimbo yacho inogona kugadziriswa chero bedzi isingakanganisi basa;Inogona kugadziriswa |

| 3 | Layer ripple pamusoro weld surface | Iyo yakabatana inofanira kuzadzwa ne solder nguva dzose;Inogona kugadziriswa |

| 4 | Kutsemuka kwepamusoro (transverse uye longitudinal) kunoitika paweld | Kana mamiriro ezvinhu achibvumira, nzvimbo yacho inogona kugadziriswa chero bedzi isingakanganisi basa;Inogona kugadziriswa |

| 5 | Kutsemuka kwepamusoro (transverse uye longitudinal) kunoitika pahwaro hwesimbi | Haina kukodzera, inoda kugadziriswa |

| 6 | Base simbi kupinda | Haina kukodzera, inoda kugadziriswa |

| 7 | Kupinda pasi uye kusina kukwana | Haina kukodzera, inoda kugadziriswa |

| 8 | spatter | Kana mamiriro ezvinhu achibvumira, nzvimbo yacho inogona kugadziriswa chero bedzi isingakanganisi basa;Inogona kugadziriswa |

| 9 | Husina nyama | Hazvibvumirwi, kugadzirisa kunodiwa |

| 10 | Iyo yekutanga yekupedzisira haina welded, uye iyo terminal ine gomba | Hazvibvumirwi, kugadzirisa kunodiwa |

| 11 | Weld inoshaikwa (gap hombe rinoenderana) | Hazvibvumirwi, kugadzirisa kunodiwa |

2 、 Kuongorora kunoparadza

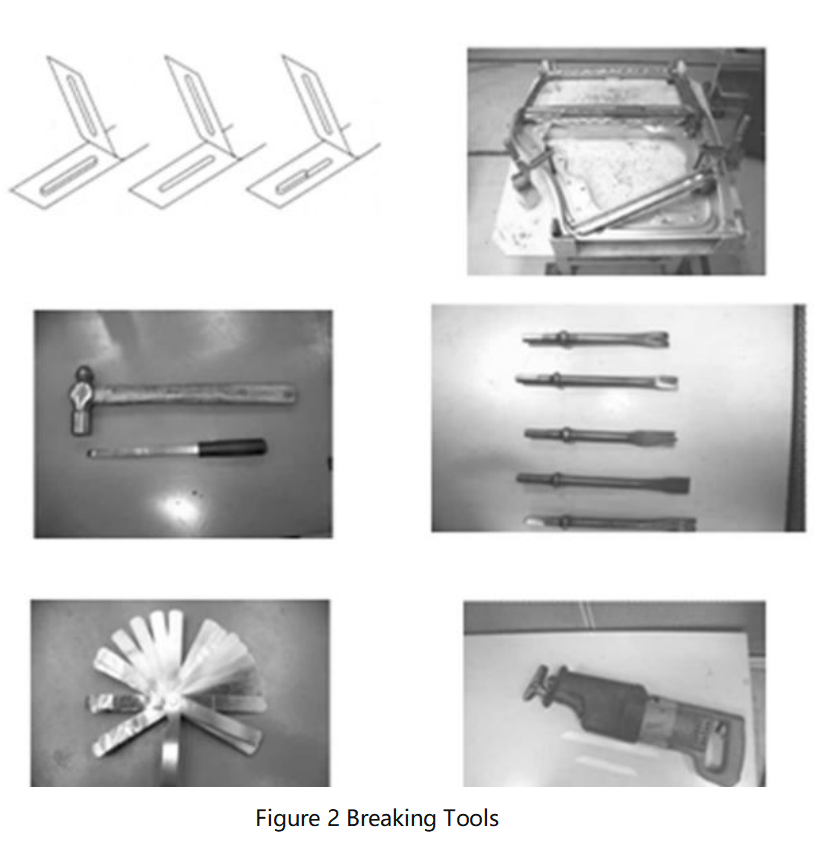

Maturusi ekuongorora anoparadza anoratidzwa mumufananidzo 2:

3, Metallographic Microscopic Analysis

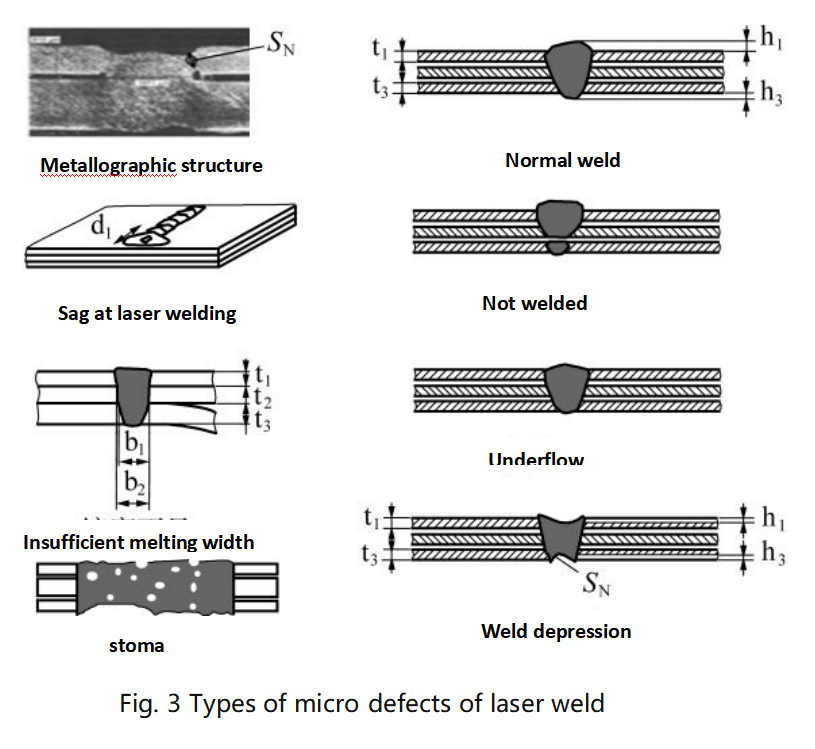

Mhando dze micro defects ye laser weld inoratidzwa mumufananidzo 3:

4 NDT

Ultrasonic, X-ray uye zvimwe zviridzwa zvinogona kushandiswa kuongorora iyo laser welding mhando.

Summary

Zvinoenderana neiyo chaiyo yekushandisa mhedzisiro yelaser welding tekinoroji muzvirimwa zvemotokari, zvinogona kuoneka kuti laser welding haingogone kuderedza huremu hwemuviri wemotokari, kuvandudza kurongeka kwemusangano wemuviri wemotokari, asi zvakare kuwedzera zvakanyanya simba remotokari. muviri, kupa vashandisi kuchengetedzwa kuri nani ivo vachinakidzwa nekunyaradza.Zvinotendwa kuti nekuenderera mberi kwekuenderera mberi kwematambudziko e-laser welding tekinoroji uye nekuenderera mberi kwekuvandudza kwekugadzira maitiro, laser welding ichave chikamu chakakosha cheramangwana remota muviri muchena kugadzira maitiro.

Nguva yekutumira: Jan-09-2023