Handheld Laser welding senge laser processing technology, laser welding tekinoroji yakashandiswa kune welding yezvikamu zvidiki zvitete kubvira 1964. Nekukurumidza kukura kweindasitiri yemotokari uye nekuenderera mberi kwekuvandudzwa kwezvinodiwa nevanhu, kusangana nezvinodiwa zvekuchengetedza, kuchengetedzwa kwezvakatipoteredza, uye kuchengetedza simba, uye kuti uwane otomatiki, kushanduka uye hungwaru kusimudzira kwekugadzira chigadzirwa chekugadzira, laser welding tekinoroji yakaiswa kumunda wekugadzira muviri wemotokari kubva kuma1980s.Zvinoenderana nehuwandu hwakakodzera, 50% ~ 70% yezvikamu zvemotokari munyika dzakasimukira dzeEurope neAmerica maindasitiri anogadziriswa nelaser, kunyanya laser welding nekucheka.Laser welding yave yakajairika maitiro mukugadzira otomatiki.

Process musimboti

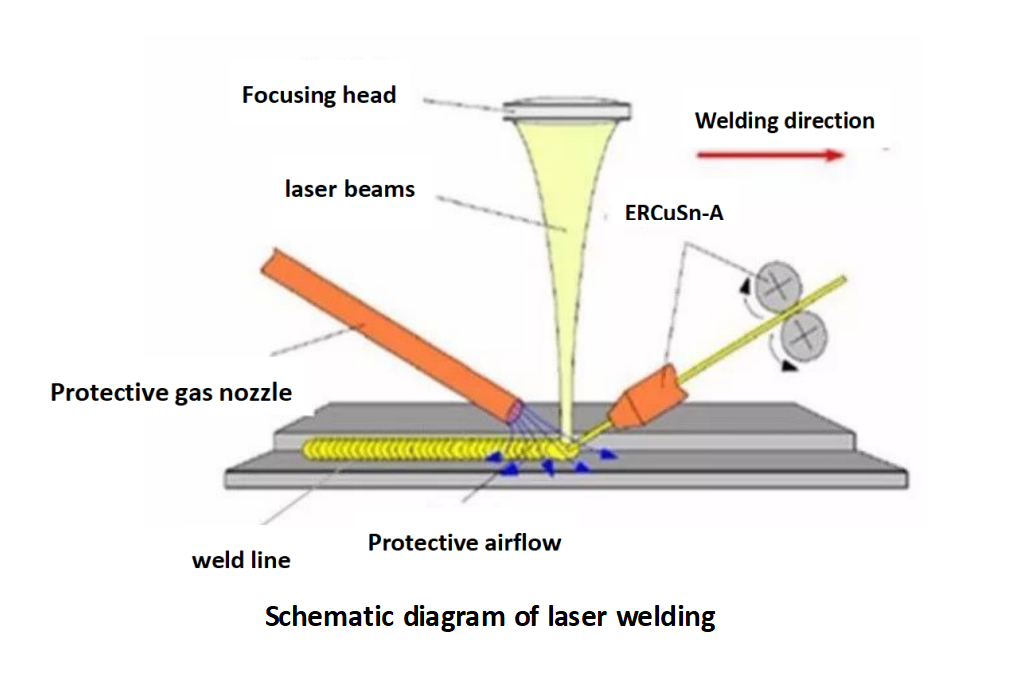

Nheyo yelaser welding ndeyekuti iyo laser beam inoburitswa nelaser jenareta inonangana pamusoro peiyo welding waya yekudziya kuitira kuti waya yekudziya inopisa nekunyungudutswa, ndiro yesimbi pamuviri wemotokari yakanyoroveswa, mukaha pakati pe simbi ndiro majoini anozadzwa, uye welding seam inoumbwa kuti pakupedzisira iwane yakanaka kubatana.Kubatana kwebrazing pakati pemhangura welding waya uye simbi ndiro inoumbwa mushure mekugadzira.Iyo copper welding wire uye simbi ndiro zvinhu zvakasiyana, uye welding layer inoumbwa navo ndiko kusanganiswa kwezvinhu zviviri zvakasiyana mushure mekupisa kwakanyanya.Kuenzaniswa neyechinyakare nzvimbo welding, iyi welding nzira ine nani welding mhando, kukurumidza kukurumidza, uye yakakwira simba rechikamu chewelding.

Zvakanakira laser hand-held welding ndezvizvi:

1.Small kupisa kwakakanganiswa zone.Iko kupisa kwekuisa kunogona kuderedzwa kusvika kune yakaderera inodiwa huwandu, uye kupisa kwakakanganiswa nzvimbo idiki, saka iyo thermal deformation ishoma.

2.Contactless.Inooneka welding, isingabatanidzi welding, hapana chikonzero chekushandisa maelectrode, hapana kunetseka nezve kusvibiswa kwe electrode kana kukuvadzwa, uye kushandiswa uye deformation yemuchina inogona kuderedzwa.

3.Laser beam iri nyore kutarisa, kurongedza uye kutungamirirwa nemidziyo yemaziso, inogona kuiswa panzvimbo yakakodzera kubva kune workpiece, uye inogona kutungamirirwa pakati pemichina, zvishandiso kana zvipingamupinyi zvakapoteredza workpiece.

4.Iyo Laser beam inogona kutariswa pane diki diki nzvimbo uye inogona otomatiki weld diki uye nepedyo zvikamu.

5.Iyo iri nyore kuona yakakwirira-kumhanya otomatiki welding nenhamba kutonga.

Nguva yekutumira: Zvita-23-2022