Kusuma shanu laser epurasitiki welding nzira

Mumakore achangopfuura, nekuenderera mberi kwekuvandudza tekinoroji, laser welding yemapurasitiki icharatidza zvishoma nezvishoma maitiro ari kukura mune ramangwana.Mumakore mashoma apfuura, mamwe laser tekinoroji haana kupaza, uye mutengo welaser wakakwira.Kuenzaniswa neyechinyakare welding, iyo yenguva imwe chete investimendi yakakura, iyo inogona kusaburitsa mabhenefiti nekukurumidza.Asi ikozvino mukana wehupfumi welaser unoratidzwa.Iyo laser welding yepurasitiki inogona kuderedza kuoma kwevagadziri kugadzira zvigadzirwa.

Parizvino, zvigadzirwa zvakawanda (kusanganisira indasitiri yemotokari semiconductor, indasitiri yemishonga uye yechikafu, nezvimwewo) zvine zvakanyanya zvinodikanwa zvekugadzirisa kurongeka uye kutaridzika kwekunaka, izvo zvinoita kuti laser welding ive nzira inodiwa pakugadzirwa kwezvinhu izvi uye inosimudzira kuenderera mberi kwe Laser welding tekinoroji.

Iyo padyo nekuenderana, tembiricha yekusanganisa uye kufananidzwa kwepurasitiki laser welding ndizvo, zvirinani kuita kwayo kuchava.Maitiro ekushandisa epurasitiki laser welding akasiyana neayo esimbi welding, kusanganisira inoteedzana circumferential welding, quasi synchronous welding, synchronous welding uye irradiation mask welding.Olay Optoelectronics ichaunza muchidimbu aya mawodhi emagetsi.

1. Profile welding

Iyo laser inofamba ichitevedza mutsara wecontour weplastic welding layer uye inonyungudusa kuti zvishoma nezvishoma isunge zvidimbu zvepurasitiki pamwechete;Kana fambisa sandwich pamwe neyakagadziriswa laser beam kuti uwane chinangwa chewelding.

Mumashandisirwo anoshanda, contour welding ine zvakakwirira zvinodikanwa zvemhando yemajekiseni akaumbwa zvikamu, kunyanya pakushandiswa kwemitsara yakaoma yewelding senge mafuta-gasi separators.Mukuita kwepurasitiki laser welding, contour welding inogona kuwana kumwe kupinza kweiyo welding mutsara, asi kupinda uku kudiki uye kusingadzoreki, izvo zvinoda kuti deformation yezvikamu zvekuumba jekiseni haifanire kunge yakakura.

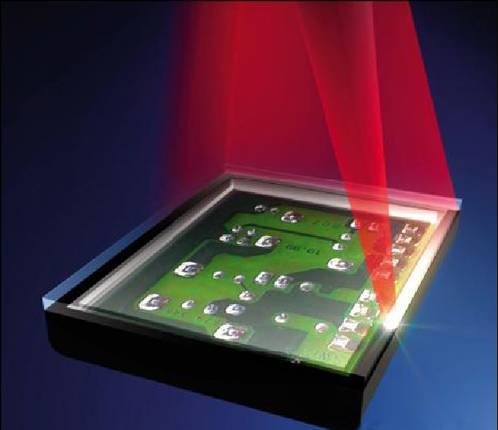

2. Synchronous welding

Iyo laser beam kubva kune akawanda diode lasers inoumbwa nezvinhu zvemaziso.Iyo laser beam inotungamirwa pamwe neiyo contour mutsara wewelding layer uye inogadzira kupisa pamusono we weld, kuitira kuti mutsara wese we contour unyunguduswe uye unobatanidzwa pamwechete panguva imwe chete.

Synchronous welding inonyanya kushandiswa mumarambi emotokari uye indasitiri yezvokurapa.Synchronous welding is a multi danda, optical shaping inoratidza mwenje nzvimbo yewelding track, inotaridzwa nekudzikisa kushushikana kwemukati.Nemhaka yokuti zvinodiwa zvacho zvakakwirira uye mutengo wose wakanyanya kukwirira, unoshandiswa zvakanyanya mukurapa.

3. Scanning welding

Laser scanning welding dhizaini

Scanning welding inonziwo quasi synchronous welding.Scanning welding tekinoroji inosanganisa ari pamusoro apa maviri welding matekinoroji, anoti, sequential circumferential welding uye synchronous welding.Iyo reflector inoshandiswa kugadzira high speed laser beam ine kumhanya kwe10 m/s, iyo inofamba pamwe nechikamu kuti isungirwe, ichiita kuti chikamu chese chewelding chidziye zvishoma nezvishoma uye chisanganise pamwechete.

Quasi synchronous welding ndiyo inonyanya kushandiswa.Muindasitiri yezvikamu zvemotokari, inoshandisa iyo XY yakakwirira-frequency galvanometer mukati.Yayo musimboti ndeyekudzora epurasitiki welding kudonha kwezvinhu zviviri.Contour welding inoburitsa kushushikana kukuru kwemukati, izvo zvinokanganisa kuiswa chisimbiso kwezvinhu.Quasi synchronization ndeyekumhanya-mhanya yekuongorora maitiro, uye nekutonga kwazvino, inogona kunyatso kubvisa kushushikana kwemukati.

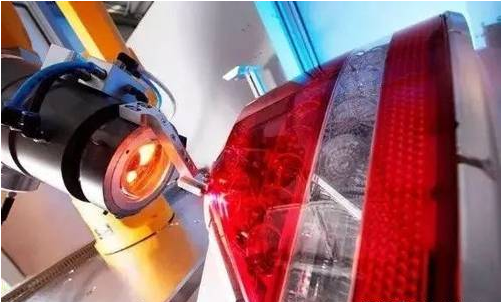

4. Rolling welding

Mufananidzo we laser rolling welding

Rolling welding ndeye innovative laser plastiki welding process, ine akawanda akasiyana mafomu.Kune marudzi maviri makuru eku rolling welding:

Yekutanga ndeyeGlobo bhora welding.Kune mhepo cushion girazi bhora kumagumo kwelaser lens, iyo inogona kutarisa laser uye kusungirira zvikamu zvepurasitiki.Mukuita welding, Globo lens inofambiswa nechikuva chekufamba kuti ipedze kukwenenzverwa nekukunguruka uchitevedza mutsara wewelding.Maitiro ese ari nyore sekunyora nechinyoreso chebhora.Globo welding process haidi yakaomesesa yepamusoro gadziriso, asi chete yepasi mold inotsigira chigadzirwa.Globo bhora welding process zvakare ine akasiyana roller roller welding process.Musiyano ndewekuti bhora regirazi kumagumo kwelens rinoshandurwa kuita cylindrical girazi dhiramu kuti riwane yakakura laser segment.Roller roller welding yakakodzera kune yakafara welding.

Yechipiri ndeye TwinWeld welding process.Iyi yepurasitiki laser welding process inowedzera simbi roller kusvika kumagumo kwelens.Munguva yewelding process, roller inotsikirira kumucheto kwemutsara we welding we welding.Kubatsira kweiyi epurasitiki laser welding process ndeyekuti iyo simbi inotsikirira vhiri haipfekwe, iyo inobatsira kugadzirwa kwakakura.Nekudaro, kudzvanywa kweiyo yekumanikidza roller kunoshanda pamucheto weiyo welding mutsara, iri nyore kugadzira torque uye kuumba kwakasiyana-siyana welding kuremara.Panguva imwecheteyo, nekuti iyo lens chimiro chakanyanya kuoma, zvakaoma kune welding programming.

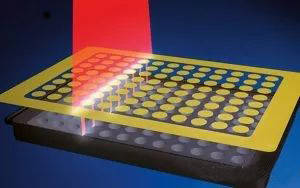

5. Irradiation mask welding

Laser irradiation mask welding diagram

Iyo laser beam inomisikidzwa kuburikidza ne template kuti inyunguduke uye isunge purasitiki.Iyo template inongoburitsa diki chaiyo chaiyo welding chikamu pane yepurasitiki layer pazasi.Iyo laser beam inongopisa chikamu chechigadzirwa chisina kuvharwa nemask.Iyi tekinoroji inogona kushandiswa kuwana yakakwirira-chaiyo welding yakaderera segumi mamicrons.

Iyo microfluidic zvikamu zvinogona kuve nemazvo uye zvakatsiga welded neiyo mask welding musimboti.Iyo geometry yechiteshi icharamba yakafanana, kudzivirira kunyunguduka kuyerera mugwara rakamanikana re 200 µ m.

Nguva yekutumira: Oct-21-2022