Iyo motokari yemotokari yemotokari yemagetsi inonyanya kuumbwa ne stator, rotor, casing, connector, rotary transformer uye zvimwe zvikamu.Naizvozvo, kumusoro kwemota yemotokari yemagetsi ndiyo gungano uye gungano, umo gungano iri chikamu chechitatu chechikamu chemota yemagetsi, gungano chikamu chechipiri chechikamu chemota yemotokari yemagetsi, uye mota yemagetsi ndiyo. chikamu chekutanga chechikamu chemotokari yemotokari yemagetsi.

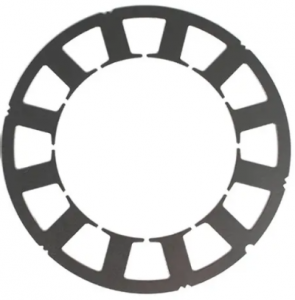

Silicon simbi sheet: kiyi chikamu chemota

Silicon simbi pepa ndicho chinhu chakakosha chemota uye magetsi mudziyo.Kuita kwayo hakusi kungoenderana zvakananga nekurasikirwa kwesimba remagetsi, asiwo kune chekuita nekuita, huwandu uye uremu hwemotokari uye transformer.

Kuita kwesilicon simbi sheet kunowanzo kudiwa sezvizvi:

1. Chimiro cheplate yakanaka uye kupfeka kwepamusoro;

2. High dimensional kurongeka uye kushoma ukobvu musiyano wendiro imwechete;

3. Iine yakanaka electromagnetic zvimiro uye zviyo zvekutarisa chimiro zvinosangana nezvinodiwa zvekushandisa.

Reform ye laser yekucheka tekinoroji yesilicon simbi pepa

- Traditional processing

Iyo yechinyakare yekugadzirisa nzira yesilicon simbi pepa inonyanya kumhanyisa-kumhanya kubaya

1.Kuvhurika kweMold kunodiwa padanho rekutanga

2.High R & D mari

- Laser kucheka

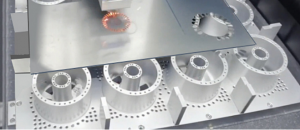

Ikozvino, laser yekucheka inoshandiswa kugadzira silicon simbi pepa, iyo inogadzirisa dambudziko rakaoma rechinyakare silicon simbi sheet processing.

1. Pfupi R & D kutenderera, hapana kuvhurika mold

2.Chero nhamba inogona kutemwa

3.Flexible uye yakanakira

(Precision alloy chiridzwa laser yekucheka muchinaEPLC6045)

EPLC6045 inotora yakasikwa granite muchina chikuva, yakakwirira-chaiyo kugadzirisa aluminium inofamba danda uye chitarisiko pepa simbi kurongedza, uye inodzivirira kupisa pendi kurapwa kuti ipe chengetedzo yakanaka uye chisimbiso chekuchengetedza chisimbiso pachigadziro chekusangana nezvinodiwa maitiro.

Positioning kururama:±3um(X1) ±5um(X2) ±3um(Y) ±3um(Z) ±15arcsec(θ);

Kudzokorodza kumira zvakanaka:±1um(X1);±3um(X2);±1um(Y);±1um(Z);±3arcsec(θ);

Plane processing range:450mm * 600mm, inovhara saizi zvinodiwa zveakawanda matsva emagetsi mota (yakakura fomati inogona kugadzirwa).

Customized makemikari midziyo:vacuum adsorption inogamuchirwa, uye iyo adsorption nzvimbo inogadziriswa zvinoenderana neyakagadzirwa chimiro.Mapombi akasiyana-siyana anogona kusarudzwa.

Nguva yekutumira: Aug-18-2022